Checking out the Perks and Applications of Heat Transfer Systems in Modern Sector

Heat transfer systems play a vital role in modern-day industry. They include numerous systems such as convection, conduction, and radiation, each adding to effective thermal management. Industries like manufacturing and aerospace benefit greatly from these systems. As innovations proceed, the assimilation of cutting-edge products and innovations assures to boost energy efficiency. This advancement raises crucial questions concerning the future ramifications for sustainability and functional expenses across several industries. What exists ahead in this recurring makeover?

Comprehending Heat Transfer Principles

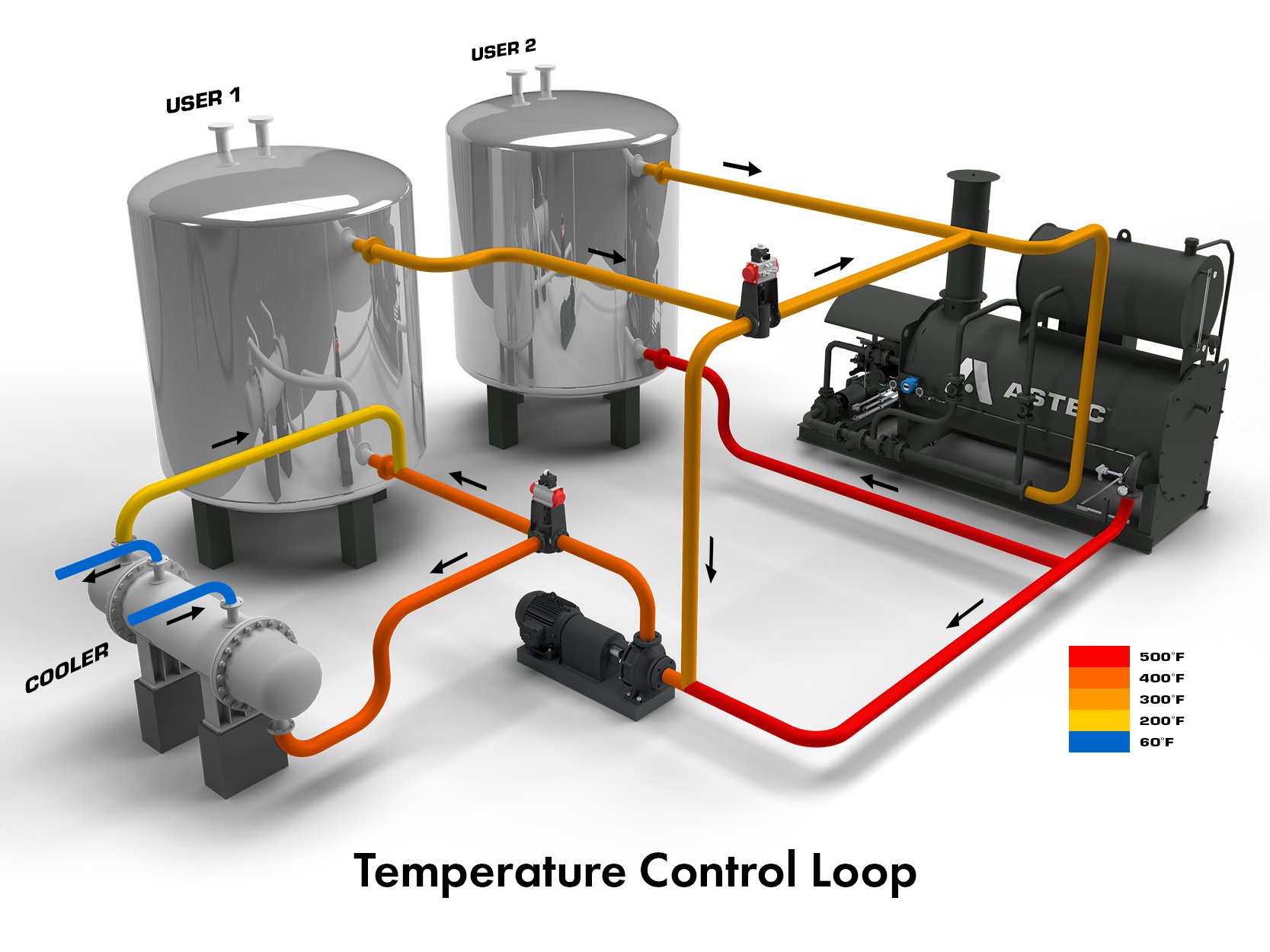

Heat transfer principles are basic to the operation of various industrial systems. These principles include the devices of radiation, convection, and transmission, each playing an essential function in taking care of thermal power. Understanding transmission entails analyzing exactly how Heat moves through strong products, while convection relate to Heat transfer in fluids, driven by liquid movement. Radiation, distinct from the various other 2, includes power transfer through electro-magnetic waves. The performance of Heat transfer impacts system efficiency, energy usage, and total performance. Efficient thermal administration is important in processes such as home heating, Heat, and cooling healing. By understanding these concepts, markets can enhance their procedures, decrease power expenses, and enhance tools longevity, thus adding to a more effective and sustainable industrial landscape.

Trick Sorts Of Heat Transfer Systems

While various industries use Heat transfer systems for diverse applications, numerous key types stick out as a result of their details functions and efficiencies. One of the most common types consist of convection, conduction, and radiation systems. Conduction systems transfer Heat through direct get in touch with in between products, making them efficient in solid-state applications. Convection systems, on the various other hand, use liquid activity to transfer Heat, suitable for home heating or cooling down gases and liquids. Radiation systems operate without a medium, counting on electro-magnetic waves to transfer Heat, suitable for high-temperature environments. Each type offers unique functions, allowing industries to customize their Heat transfer options based upon functional needs, power performance, and cost-effectiveness. Understanding these systems is vital for enhancing performance in numerous industrial setups.

Industrial Applications of Heat Transfer Technologies

The application of Heat transfer modern technologies in industry plays a vital function in improving power effectiveness and maximizing processes. DVS Heat Transfer Systems. By implementing sophisticated Heat exchange systems, companies can considerably lower their environmental influence while boosting general performance. This combination not only promotes sustainability but likewise aligns with modern-day regulative and consumer needs for greener techniques

Energy Performance Improvements

As industries significantly prioritize sustainability, power performance enhancements in Heat transfer innovations have actually ended up being crucial for lowering operational prices and ecological influence. Boosted Heat exchangers, as an example, utilize innovative materials and layouts to make best use of thermal performance while lessening energy consumption. Furthermore, integrating variable speed drives in pumping systems enables much better control of liquid flow, leading to considerable energy savings. The application of clever sensors and automation provides real-time tracking, making it possible for changes that enhance energy use. In addition, waste Heat healing systems capture excess thermal energy, converting it right into functional power. These innovations not just enhance energy performance however likewise add to an extra sustainable commercial landscape by decreasing greenhouse gas discharges and sustaining compliance with ecological policies.

Process Optimization Techniques

Refine optimization strategies are crucial in boosting the efficiency and effectiveness of Heat transfer innovations in commercial applications. These methods entail refining processes to make best use of Heat transfer efficiency while reducing power intake and operational costs. Techniques such as computational liquid characteristics (CFD) modeling permit designers to simulate and examine Heat transfer circumstances, determining locations for enhancement. In addition, real-time tracking systems can provide valuable information on temperature level slopes and flow prices, enabling adjustments that enhance performance. In addition, carrying out sophisticated control strategies, such as anticipating analytics, can improve system responsiveness to varying operational demands. By applying these optimization strategies, sectors can attain greater thermal efficiency, reduced downtime, and improved item high quality, inevitably leading to enhanced competition in the industry.

Environmental Impact Decrease

While industrial Heat transfer modern technologies are vital for functional effectiveness, their application also offers possibilities for considerable environmental impact reduction. By boosting power performance, these systems decrease fuel intake, causing lower greenhouse gas emissions. For example, progressed Heat exchangers can recoup waste Heat, rerouting it to preheat incoming fluids, consequently decreasing energy requirements. On top of that, the assimilation of Heat transfer modern technologies in sustainable energy systems, such as solar thermal and geothermal applications, sustains the shift to lasting methods. Industries that utilize these technologies additionally profit from minimized operational costs and improved governing conformity. Generally, the tactical execution of Heat transfer systems not just reinforces productivity however additionally cultivates a much more sustainable commercial landscape, adding to international environmental objectives.

Benefits of Efficient Heat Transfer Systems

Effective Heat transfer systems provide substantial benefits in modern sector, mainly through enhanced power performance and expense reduction. By maximizing thermal monitoring, these systems reduce power waste, bring about lower operational costs (DVS Heat Transfer Systems). Services can achieve better sustainability and enhanced profitability.

Power Efficiency Improvements

As industries progressively prioritize sustainability and cost-effectiveness, energy performance improvements in Heat transfer visit our website systems have actually become an essential emphasis. Improved performance in these systems brings about minimized power intake, allowing centers to run even more sustainably. By maximizing Heat transfer methods, industries can lessen waste Heat and attain far better thermal administration, greatly lowering their ecological impact. Advancements in innovations such as Heat exchangers and insulation products contribute to boosted efficiency and dependability. Executing energy-efficient Heat transfer options not only supports compliance with regulatory requirements yet additionally cultivates a culture of development within companies. Ultimately, these renovations are important in straightening industrial procedures with global energy conservation goals, paving the means for a more sustainable future in manufacturing and handling industries.

Cost Decrease Opportunities

By enhancing Heat transfer systems, sectors can expose significant cost decrease opportunities that boost their bottom line. Reliable Heat transfer lowers power consumption, bring about reduced utility expenses and minimizing functional costs. In addition, enhanced system performance decreases the demand for maintenance and repairs, furthermore conserving expenses with time. Enhanced Heat transfer can likewise expand devices life expectancy, allowing firms to delay capital investment on substitutes. Waste Heat recuperation systems can transform excess Heat right into useful energy, better driving down costs. These systems not only simplify processes however additionally add to sustainability his comment is here initiatives, positioning companies favorably in an increasingly eco-conscious market. On the whole, the financial advantages of reliable Heat transfer systems are considerable and important for competitive advantage.

Technologies in Heat Transfer Solutions

How can modern sector enhance its operations with ingenious Heat transfer options? By taking on innovative products and technologies, markets can substantially boost thermal efficiency and performance. Innovations such as nanofluids, which enhance Heat transfer capacities past conventional liquids, and phase change materials that store and release thermal energy, are gaining traction. Additionally, the assimilation of clever sensing units and IoT devices permits real-time monitoring and optimization of Heat transfer procedures, lowering waste and boosting system responsiveness. Moreover, additive manufacturing techniques make it possible for the production of even more intricate Heat exchangers that take full advantage of surface location while lessening material use. Jointly, these advancements drive operational efficiency and create affordable advantages in numerous industries, including production, energy, and aerospace.

The Role of Heat Transfer in Sustainability Efforts

While the press for sustainability continues to improve markets, the role of Heat transfer technologies comes to be progressively essential in attaining ecological objectives. Efficient Heat transfer systems help with power effectiveness by maximizing thermal administration in numerous procedures, substantially minimizing power usage and greenhouse gas exhausts. As an example, progressed Heat exchangers are used in industrial applications to reclaim waste Heat, thus decreasing energy waste. Additionally, advancements such as stage adjustment products improve thermal storage space, adding to renewable resource combination. Furthermore, the fostering of lasting fluids in Heat transfer systems can decrease ecological influence. By prioritizing reliable Heat transfer, industries not only boost operational performance however additionally straighten with global sustainability initiatives, promoting a cleaner, a lot more lasting future.

Regularly Asked Questions

How Do Heat Transfer Solutions Effect Power Costs in Manufacturing?

Heat transfer systems markedly affect energy prices in production by enhancing efficiency, minimizing waste, and maximizing thermal administration. These renovations bring about lower functional expenses, ultimately benefiting overall efficiency and success in industrial procedures.

What Upkeep Is Needed for Heat Transfer Systems?

Maintenance for Heat transfer systems consists of regular evaluations, cleaning of elements, inspecting fluid levels and problems, changing worn parts, and guaranteeing proper insulation. These actions boost effectiveness, prolong lifespan, and prevent pricey malfunctions in operation.

Are There Safety And Security Interest In Heat Transfer Solutions?

Security worry about Heat transfer systems include prospective leaks, pressure build-up, and thermal dangers. Proper style, regular maintenance, and adherence to safety and security procedures are vital to alleviate these risks and ensure risk-free operation in industrial environments.

Exactly How Can I Select the Right Heat Transfer System for My Company?

Choosing the right Heat transfer system entails assessing variables such as efficiency, application demands, budget constraints, and safety criteria. A complete evaluation of these components will certainly help guarantee ideal performance and integrity in organization procedures.

What Prevail Failures in Heat Transfer Systems and Their Reasons?

Recognizing conduction includes assessing just how Heat moves with solid materials, while convection pertains to Heat transfer in fluids, driven by fluid movement. By maximizing Heat transfer techniques, sectors can reduce waste Heat and achieve better thermal monitoring, considerably decreasing their environmental influence. Waste Heat healing systems can change excess Heat into usable power, better driving down expenses. Advanced Heat exchangers are made use of in industrial applications to recover waste Heat, thus decreasing power waste. Common failings in Heat transfer systems include leaks, deterioration, and inefficient Heat exchange.